Finishing

Powder Coating

PEM CORPORATION 2 Stage MODULAR Wash Booth

This wash booth sprays a mixture of water and phosphate at high pressure which allows us to clean tanks and parts so they are free of dirt and oil before the powder process. The phosphate also prepares the surface for a better adhesion for the powder-coat.

Gas-Cat Technologies Infrared Oven

This oven is utilized before the powder spraying process to dry the parts. Another benefit of this oven, is it pre-heats the parts for better adhesion and proper cohesion of the powder across the entire part.

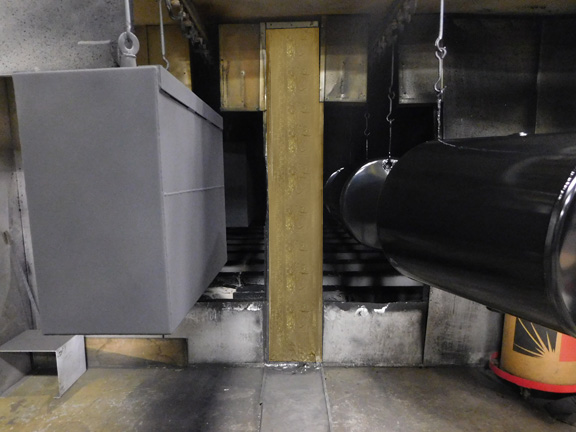

JBI Powder Coating Spray Booth

JBI Powder Coating Spray Booth

This two-sided spray booth is used to spray the powder onto the parts from both sides. This booth is hand operated, which allows for proper coverage and permits us the versatility to be able to address every surface of the tank that wouldn't normally be reached with automated operations.

SJS PC200 Gas Fired Curing Oven

SJS PC200 Gas Fired Curing Oven

Gas fired ovens have some advantages, as opposed to infrared or direct heat. The main reason is that it allows for the entire air space to be heated, permitting even heat distribution for proper and balanced curing of the powder.

Parker Ionics GX7500S Control System

Parker Ionics GX7500S Control System

Parker Ionics is the industry leader in powder-coating control systems. We utilize four of these units to allow for quick change over for custom color options. These top of the line units allow us to achieve fast and even distribution of powder across every tank and part.

American Mobile Power is constantly striving for modernization and better process flow. We continually add new/better equipment to increase output and improve quality. We are actively developing new solutions to improve our team and to satisfy our customer's needs, this allows us to stay competitive and adds value to our team and customers.