Assembling and Packaging

Standard Sized products are boxed and Pallet-Loaded,

Other Products are directly pallet-loaded for shipment.

Boxed Tanks

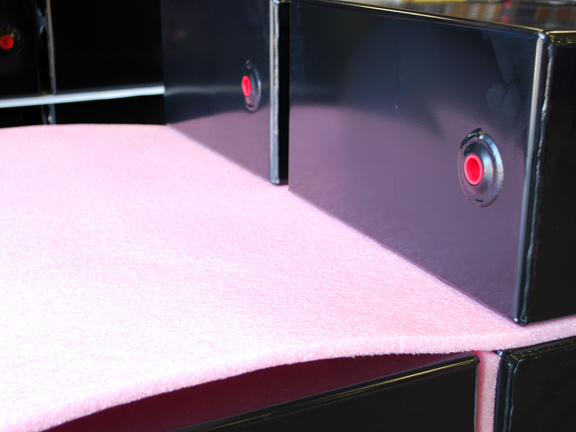

Once all the parts are installed, every product is throughly cleaned to remove any dust or debris that remains.

Once the foam process is complete, the box is closed and then strapped and/or glued. This step ensures that boxes do not open during transport.

After strapping, boxes are stacked onto pallets according to order and banded down.

The final step is to place the finished pallet on the wrapper to secure the freight for shipment.

Pallet-LOADED TANKS

Tanks that are too big or awkward to be packed in a box are pallet-loaded.

Special care is used with this packaging process to prevent damage or contamination during shipment.

The first step is to install the fill assembly and any other accessories that the tank may require, i.e. sight temp gauges, plugs, port covers.¹²

The first step is to install the fill assembly and any other accessories that the tank may require, i.e. sight temp gauges, plugs, port covers.¹²

Next, any remaining open ports are plugged with plastic cap plugs to prevent contamination.

A sheet of thick plastic or cardboard is placed on an empty pallet and the tanks are stacked neatly on top.